Precision shooting demands precision equipment, and when it comes to the AR-10 platform, nothing influences accuracy and performance more than your barrel selection.

As we move through 2025, the market for .308 barrels continues to evolve with advanced manufacturing techniques, materials, and designs that push the boundaries of what's possible for both competitive shooters and hunting enthusiasts.

Whether you're building a new rifle or upgrading an existing one, selecting the right barrel is crucial for achieving the accuracy, reliability, and longevity you expect from your investment.

In this comprehensive guide, we'll explore the top AR-10 barrels available this year, breaking down the critical factors that separate exceptional barrels from merely adequate ones. From premium materials to optimal twist rates, the team at AR15 Parts has researched and compiled everything you need to make an informed decision for your next build or upgrade.

Choose the Right Barrel Material for Long-Term AR-10 Accuracy

The foundation of any quality AR-10 barrel begins with its material composition. In 2025, manufacturers continue to refine their metallurgical processes, offering shooters more options than ever before.

Stainless steel barrels remain incredibly popular for precision builds due to their inherent accuracy potential. These barrels typically feature better machining tolerance and smoother bore surfaces than their chrome-moly counterparts.

Premium stainless options from manufacturers like Wilson Combat offer exceptional accuracy; their match-grade barrels regularly produce sub-MOA groups with quality ammunition. The 20" 308 WIN Upper with Wilson Combat Super Sniper Fluted barrel exemplifies this premium approach with its glass-beaded stainless steel construction.

Chrome-moly-vanadium (CMV) barrels provide excellent durability and heat resistance at a more accessible price point. Companies like Ballistic Advantage have mastered the balance of performance and value with their modern series tactical government barrels. These barrels undergo stress-relief processes to enhance accuracy while maintaining the durability CMV is known for.

Newer carbon fiber composite barrels have made significant inroads in the AR-10 market. These ultra-lightweight options reduce overall rifle weight by up to 60% compared to traditional steel barrels while maintaining impressive accuracy. The trade-off comes in heat management during sustained fire and a higher price point, making them specialized tools rather than all-purpose solutions.

The barrel's material directly influences not just accuracy but also longevity, weight, and heat management, which are all critical factors in selecting the ideal barrel for your specific application.

Match Barrel Length to Your Shooting Style and Purpose

Barrel length is perhaps the most visible characteristic that will influence your AR-10's performance envelope. The right length depends entirely on your intended use case.

For precision long-range shooting, 20- to 24-inch barrels remain the gold standard in 2025. These longer barrels extract maximum velocity from the .308 Winchester cartridge, extending effective range and minimizing wind drift. The additional sight radius also benefits those using iron sights. The trade-off comes in overall weight and maneuverability, making these barrels less ideal for field use in tight quarters.

Mid-length barrels (16-18 inches) represent the versatility sweet spot for many shooters. The 16" 308 WIN Upper with Ballistic Advantage Tactical Government barrel offers an excellent balance of ballistic performance and handling characteristics. These barrels still achieve approximately 90-95% of the velocity of longer barrels while significantly improving handling dynamics and reducing overall weight.

Shorter barrels (under 16 inches) require NFA registration as short-barreled rifles but offer maximum maneuverability for tactical applications. The velocity penalty becomes more pronounced with these lengths, effectively limiting practical range to 400-500 yards for most shooters.

A crucial consideration for 2025's barrel selection is understanding the relationship between barrel length and your chosen cartridge. The .308 Winchester generates optimal performance from 16-20 inch barrels, with diminishing returns beyond this range for most applications.

Balance Barrel Profile and Weight for Optimal Handling

The profile of your AR-10 barrel, namely its external diameter, and how it changes along the length significantly impacts handling, heat management, and accuracy potential. Heavy or bull profile barrels offer superior heat management and vibration dampening, making them ideal for precision shooting applications where the consistent point of impact is crucial.

The trade-off is substantial; these barrels can add significant weight to your build, making them less suitable for field use or any application requiring mobility. Key advantages of bull profiles include:

- Enhanced accuracy during sustained fire

- Reduced barrel whip and harmonic disruption

- Greater resistance to point-of-impact shifts as the barrel heats

Medium or government profile barrels represent a practical compromise for most shooters. These barrels feature a thinner profile under the handguard with increased diameter at the muzzle. This design originated to support mounting rifle grenades, but provides good balance between weight and heat management for modern shooters.

Lightweight and pencil profile barrels prioritize weight reduction, with some modern designs weighing half as much as their bull-profile counterparts. Modern manufacturing techniques have improved the accuracy potential of these barrels, but they remain susceptible to point-of-impact shifts during rapid fire as heat builds quickly in the thinner steel.

Fluted barrels, like those featured in the Wilson Combat Super Sniper series, offer an intelligent compromise, removing material to reduce weight while maintaining rigidity and surface area for cooling. The fluting process adds manufacturing complexity and cost, but creates a barrel that performs better than its weight would suggest.

Select the Ideal Twist Rate for Your Preferred Bullet Weights

The twist rate of your AR-10 barrel, expressed as 1:x (one rotation per x inches), critically influences which bullet weights stabilize correctly in flight. In 2025, manufacturers continue refining their twist rate offerings to match modern ammunition trends.

For .308 Winchester, faster twist rates have become increasingly common as shooters embrace heavier match-grade bullets. The traditional 1:12 twist rate adequately stabilizes bullets up to approximately 168 grains, which served military and hunting applications well for decades.

However, modern precision shooting has pushed boundaries with heavier projectiles. Current optimal twist rates for different bullet weights include:

- 1:10 Twist: Excellent all-around choice stabilizing bullets from 150-180 grains

- 1:8 Twist: Ideal for heavy match bullets from 168-220+ grains

- 1:12 Twist: Best suited for lighter bullets under 168 grains

Selecting the appropriate twist rate involves honestly assessing your primary use case. Competition shooters often prefer faster twists to accommodate heavy, high-BC match bullets, while hunters might opt for more moderate twists that work well with their preferred hunting ammunition.

Over-stabilization (using a twist rate too fast for a given bullet) can cause accuracy issues with lighter projectiles, while under-stabilization leads to erratic flight and keyholing. Working with the experts at AR15 Parts can help ensure your barrel selection matches your ammunition preferences.

Understand Chamber and Throat Specs to Boost Accuracy

Beyond the visible aspects of barrel selection, the precision and specification of the chamber and throat significantly impact both accuracy and reliability in AR-10 platforms. Match-grade chambers typically feature tighter tolerances than mil-spec alternatives, enhancing accuracy by reducing the "slop" that allows cartridges to sit inconsistently in the chamber.

These precision chambers demand quality ammunition but reward shooters with improved consistency and accuracy potential. Many top-tier manufacturers now use specialized reamers that create chambers with minimal headspace variation.

The barrel's throat (leade) design influences both accuracy and barrel life. Longer throats reduce pressure and extend barrel life but may compromise accuracy. Shorter, tighter throats enhance accuracy with specific loads but accelerate throat erosion. Modern premium barrels often feature optimized throat designs that balance these competing factors.

With advancements in manufacturing precision, hybrid chamber designs have gained popularity in 2025's premium barrels. These chambers combine match-grade dimensions with slightly enhanced tolerances in critical areas to maintain reliability with a broader range of ammunition while preserving most accuracy benefits.

For reloaders, understanding your barrel's chamber and throat specifications becomes even more important as you can tailor your loads to work optimally with your specific barrel. Many premium barrel manufacturers now provide detailed chamber specifications to facilitate this process.

Extend Barrel Life with Advanced Coatings and Treatments

The internal and external treatments applied to AR-10 barrels can dramatically influence performance and service life, with 2025 bringing several advancements in this area.

Chrome lining remains popular for military-style builds focused on durability and heat resistance. While chrome lining sacrifices some accuracy potential compared to unlined match barrels, modern application techniques have narrowed this gap considerably. Chrome-lined barrels offer superior corrosion resistance and significantly extended service life, particularly valuable for high-volume shooters.

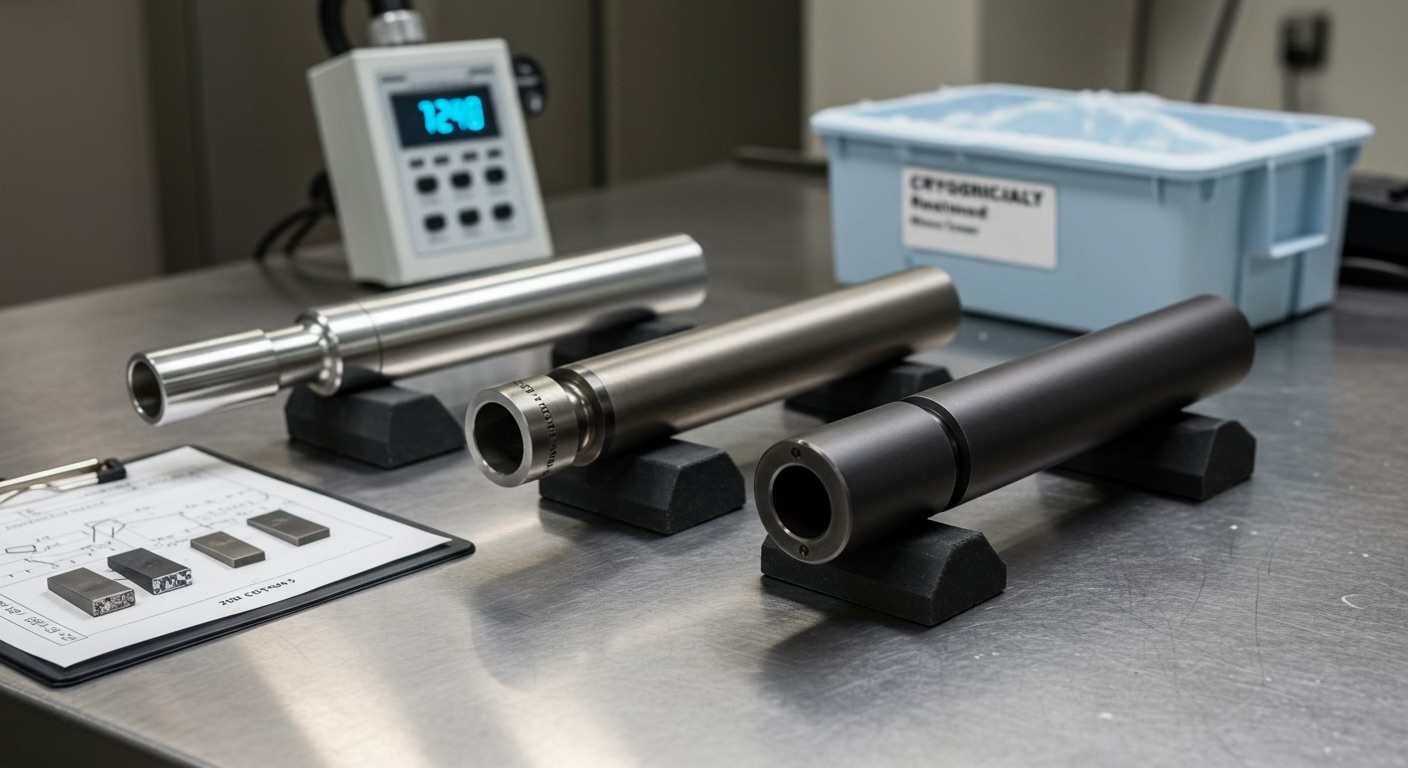

Nitriding (also called Melonite, Tennifer, or salt bath nitride) has become increasingly common as an alternative to chrome lining. This surface conversion process hardens the barrel's surface without adding material that might affect dimensions. Nitrided barrels offer excellent corrosion resistance, enhanced durability, and preserve more accuracy potential than traditional chrome lining.

Cryogenic treatment involves cooling barrels to extremely low temperatures (-300°F) then slowly returning them to ambient temperature. This process aligns and relieves stresses in the crystalline structure of the steel, potentially enhancing accuracy and extending barrel life. While scientific validation remains mixed, many precision barrel makers offer this treatment as an option.

External barrel finishes have also evolved, with PVD (Physical Vapor Deposition) coatings offering superior wear and corrosion resistance compared to traditional parkerizing or phosphate treatments. These thin-film coatings add minimal dimension while providing exceptional protection.

Explore the Top AR-10 Barrel Brands Leading in 2025

The market for high-quality AR-10 barrels continues to evolve, with several manufacturers establishing themselves as industry leaders through consistent quality and innovation.

Criterion Barrels maintains its reputation for exceptional quality control and consistent accuracy. Their chrome-lined and stainless match-grade barrels feature hand-lapped bores and optimized chambers that deliver match-grade accuracy with appropriate ammunition. Their barrel manufacturing process combines modern CNC precision with traditional hand-finishing techniques.

Proof Research has revolutionized the carbon fiber barrel market with their carbon-wrapped barrels that reduce weight while maintaining accuracy. In 2025, their AR-10 barrel offerings have expanded to include more profile and length options with their patented manufacturing process.

Wilson Combat continues producing some of the finest AR-10 barrels available, with their Super Sniper series representing the pinnacle of accuracy potential in a production barrel. Their fluted stainless steel match barrels feature precision-machined chambers and proprietary rifling that consistently produces sub-MOA groups.

Faxon Firearms has established itself as a value leader, offering quality barrels at accessible price points. Their Match Series .308 barrels feature button rifling, stress-relieved steel, and nickel-teflon extensions that ensure smooth feeding and extraction.

Ballistic Advantage, a division of Aero Precision, continues to offer an excellent performance-to-price ratio with its Modern Series barrels. These barrels feature quality materials and manufacturing processes while remaining accessible to most builders.

Frequently Asked Questions

What is the ideal barrel length for an AR-10 rifle?

The ideal barrel length depends entirely on your intended use. For maximum velocity and long-range precision, 20- to 24-inch barrels offer the best ballistic performance. For a versatile all-purpose rifle, 18 inches provides an excellent balance of velocity and handling

For more tactical applications where maneuverability is paramount, 16-inch barrels offer good performance while keeping overall length manageable. Consider that the .308 Winchester cartridge performs most efficiently in barrels between 16-20 inches, with diminishing returns beyond that length for most practical applications.

How often should I replace my AR-10 barrel?

Barrel life varies dramatically based on several factors: barrel material, firing schedule, ammunition type, and cleaning regimen. A quality chrome-lined or nitrided barrel firing standard pressure .308 ammunition might last 8,000-10,000 rounds before accuracy begins to degrade.

Match-grade stainless barrels typically offer shorter service lives of 5,000-8,000 rounds when firing full-power loads. Factors that accelerate wear include rapid fire (heating), hot loads, and inadequate cleaning. Regular inspection of the crown and throat area will help identify when replacement becomes necessary.

What's the difference between a .308 Win and a 7.62 NATO barrel?

While physically similar, these specifications have important differences. The .308 Winchester is a commercial SAAMI specification with typically higher pressure ratings (62,000 PSI) than the military 7.62×51mm NATO specification (approximately 50,000 PSI).

.308 Winchester chambers tend to have tighter dimensions for enhanced accuracy, while 7.62 NATO chambers often feature more generous dimensions for reliability with varied ammunition. Most modern AR-10 barrels with .308 Winchester chambers will safely fire both cartridges, but the reverse isn't always true. Always verify your barrel's specific chamber before using commercial .308 Winchester ammunition.

Do heavier barrels improve accuracy?

Heavier barrels can improve practical accuracy through several mechanisms. The additional mass absorbs heat more effectively, reducing point-of-impact shifts during sustained fire. Heavier barrels also resist harmonic vibration better than lighter profiles, potentially producing more consistent shot placement.

However, a poorly manufactured heavy barrel won't outperform a precision-made lightweight barrel. For benchrest shooting and situations where absolute precision matters more than portability, heavier barrels typically offer advantages. For field use where weight impacts shooter performance, lighter barrels often represent a better overall compromise.

How important is barrel break-in for a new AR-10 barrel?

Opinions on barrel break-in vary widely among manufacturers and precision shooters. Traditional break-in procedures involve careful cleaning between initial shots to remove machining residue and smooth microscopically rough spots in the bore.

Modern manufacturing techniques have reduced the necessity for extensive break-in with many barrels. Follow your manufacturer's specific recommendations, as some premium barrels with hand-lapped bores require minimal break-in while others benefit from a structured process.

Generally, a moderate approach involving cleaning after the first few shots, then after 5-shot groups for the first 20-30 rounds, strikes a reasonable balance for most quality AR-10 barrels.

Build Your Best AR-10 Yet with the Right Barrel Choice

Selecting the ideal AR-10 barrel for your specific needs requires balancing numerous factors, including intended use, desired accuracy, weight considerations, and budget constraints. The market in 2025 offers more high-quality options than ever before, from lightweight carbon fiber composites to match-grade stainless steel designs.

Remember that the perfect barrel represents a personal choice based on your shooting style and requirements; there is no universal "best" option. Consider working with knowledgeable professionals who can guide your selection process and ensure compatibility with your complete build.

For expert advice on selecting the perfect components for your AR-10 project and access to premium barrels from top manufacturers, explore our extensive selection of quality components and complete upper assemblies.

Connect with AR15 Parts for Premium AR-10 Barrels and Builds

Choosing the right AR-10 barrel is a key part of building a rifle that delivers consistent performance where it matters most, whether on the range, in the field, or competition. At AR15 Parts, we offer a wide range of match-grade barrels, upper assemblies, and precision parts built to meet the demands of serious shooters.

Contact AR15 Parts today to get expert advice and explore the best barrel options for your 2025 AR-10 build. Whether you're refining a competition rifle or upgrading a duty-ready platform, we’re here to help.